Reviewing Performance Records Reduces the Risk of Selecting a Supplier With a Poor Track Record

In life or in business, gamble-taking has benefits and may even exist an essential ingredient of success.

Quite the contrary when it comes to procurement – the concluding thing you want is hazard.

A smoothly-functioning procurement process means standardized, reliable relationships with vendors, your squad, and your customers.

Ultimately, by understanding and managing procurement risks, yous tin streamline procurement procedures to manage and reduce them.

In this article nosotros'll give yous a breakdown of the leading procurement risks and how you tin can manage them effectively.

Want to spring ahead? Click here:

- Why is it so important to manage procurement risks?

- The 7 nigh common procurement risks

- How can you lot minimize procurement risks?

Why is it and then important to manage procurement risks?

When procuring goods and services for your business, you lot must consider the risks attached at every stage.

From unreliable vendors to late deliveries, the risks of poor procurement are diverse.

For starters, mistakes and delays in the procurement process tin pb to wasted hours chasing documentation or remedying errors.

Looking at the sheer volume of potential procurement risk factors, information technology'south clear you demand to approach supply chain risk management from the outset.

To manage risks from the beginning, companies should utilize effective forecasting methods.

For 30% of retailers and manufacturers, forecasting future needs is their biggest claiming. This isn't surprising, considering that 86% don't have analytical systems which would allow them to analyze by needs to anticipate time to come requirements.

The problem is that without sophisticated forecasting and procurement planning, you'll struggle to understand when and what you need to order.

To streamline risk cess processes and risk direction solutions in 2020, information technology'southward essential you lot found a firm technological grounding.

With procurement engineering science, you'll be able to monitor and effectively manage all stages of the procurement process to help identify bottlenecks as they occur. This prevents risks from blossoming into catastrophes.

Correct now, two-thirds of retailers complain that supply chain technology doesn't help them much beyond daily tasks.

To manage potential risks effectively, implement procurement technology that helps yous forecast for the time to come as well every bit monitor each stage of the procurement process in depth.

That'southward how High Hopes Therapeutic Riding streamlines its supply chain adventure management procedures.

(Epitome Source)

By migrating from a paper take chances direction process to frevvo'southward paperless workflow automation software, High Hopes solved this issue of missing information and wrong chance reporting.

At present, thanks to a clear digital inspect trail, information technology's easy for the Program Manager to consistently oversee the processes, to forbid risks from evolving into problems.

The seven nearly mutual procurement risks

Procurement can exist challenging, especially with and then many potential risks littered along the supply chain.

Luckily, with a piddling forethought, your procurement squad can programme ways to manage the risks within your procurement system.

Here are some of the most common procurement risks that you should keep an heart on.

#1 – Inaccurate internal needs analysis

When a department or business unit identifies the need for a production or service, it kicks off the procurement process.

At this stage, the risks are obvious:

- Overstatement or understatement of the need

- Unrealistic timescales and schedules

- Inadequate upkeep

- Poorly-designed requirements

While information technology's obvious that these risks outcome in wasted time and money, the real problem lies in their knock-on effects.

Wrong forecasting and budgeting at the get-go may cause you to brand a concatenation of incorrect decisions downwards the line.

For example, y'all may choose a vendor that's besides expensive or you may buy far too many of i production.

This may crusade the unsold stock to pile up, increasing storage costs. Or yous may find you can't afford to pay a vendor for the adjacent batch of goods.

These delays frustrate today'south impatient customers. This client dissatisfaction has an outsized negative touch on your brand. One in three people volition leave a favorite brand after just one bad feel.

#ii – Poor vendor pick

For a smooth-running performance, you need a reliable and stable supply of products and services.

Without dependable vendors and robust vendor management systems, your procurement team spends their time remedying problems rather than fulfilling their bodily roles.

The risks of poor vendor choice include:

- Low-quality products

- The vendor might not evangelize what they say they can

- The supplier might non evangelize on time

- The vendor might not uphold the correct ethical standards

- The supplier could be not-compliant

Accept a look at the rental car company, Hertz…

After hiring Accenture to deliver a highly interactive new website, Accenture failed to deliver on the promised functionalities.

The site was delayed twice, resulting in huge financial impacts for Hertz.

Hertz sued the multinational company for $32 meg.

Select high-quality vendors by exploring reviews of their products and services. Look for awards, ratings, and customer success stories that prove the quality of the supplier.

#3 – Disorganized vendor management

To prevent procurement mishaps due to breakdowns in vendor relationships, you need to assess the post-obit risks:

- Communications and relationship management

- Account/Guild direction processes

- In-house supplier processes you may take to work with

- Data management

According to a contempo survey, nigh 60% of companies have taken measures to strengthen the quality of their supplier relationships.

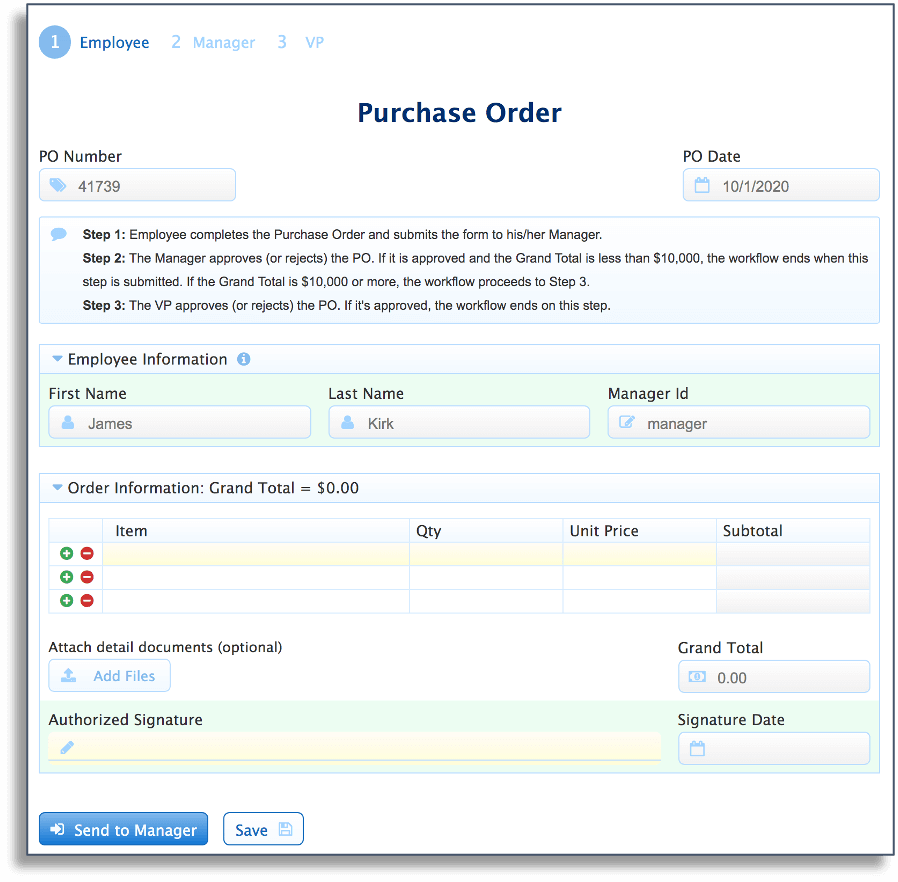

For instance, streamlining your purchasing order procedure by digitizing and automating it (through customizable forms from frevvo, beneath), means happier vendors, authentic record-keeping, and the emptying of homo mistake.

Foster resilient vendor relationships with clear communication channels, streamlined purchasing systems, and strong feedback mechanisms.

Try automating your vendor management systems with procurement automation software to nurture these relationships.

#4 – Non-compliance and crude contract management processes

Depending on your business organization model and the vendors yous're buying from, you may need to consider procurement legislation.

While private procurement has little in the way of legislation, certain legal requirements must be met for public procurement.

This is especially important for public educational institutions looking to negate procurement compliance risks.

If you don't run across these legal requirements at every stage of the procurement process, you gamble huge fines and other penalties.

Moreover, your vendor contracts need to be right and legal. This means that your contract direction procedure should address the potential risks associated with incorrect, incomplete, and outdated information.

For instance, next-generation procurement engineering science will flag incorrect or missing data. This prevents the take chances of fines from incorrect inspect trails.

#5 – Error-prone, manual internal processing

Manual processing amplifies supply concatenation adventure factors considerably as yous're far more than likely to make errors when forms are mitt-written. Paper copies are too likely to go lost when transferred from person to person for approval.

Procurement chance factors associated with transmission processing include:

- Fault-ridden documentation

- Lost forms and data

- Delayed approvals

- Wasted time remedying mistakes and chasing paperwork

Migrating to paperless processing is a smart idea. One-half of all concern leaders place a reduction in errors as one of the major reasons for switching from manual to automatic procurement processing.

#vi – Delays in procurement

Constant mistakes in the procurement process lead to delays equally your procurement squad is constantly tasked with fixing problems rather than moving procurement processes forth.

And the sheer laborious nature of manual procurement procedures means staff spends hours inputting, updating, and searching for information and documentation.

On the bright side, 54% of employees say that automation of menial tasks could save them up to 240 hours per year.

With digital procurement software, you'll exist able to automate purchasing orders and procurement approvals, while monitoring for bottlenecks in the concatenation.

#7 – Talent shortages

To succeed in the 21st century, a business organization must attract and retain world-class talent. The procurement department is no exception. A recent cursory from DHL Enquiry predicts severe talent shortages for supply concatenation professionals, so you demand to programme to stalk this risk ahead of time.

Talent shortage risks you may encounter in the procurement process include:

- High need for certain procurement professionals

- High demand causes salaries for procurement professionals to inflate beyond your budget

- Understaffing slows downward your procurement processes

- Unqualified staff make lots of mistakes

- Annoying, lengthy, complex awarding/interview processes scare off superlative candidates

Minimize talent shortage risks with strong hiring processes that streamline onboarding to arrive easy to identify high-quality procurement professionals to join your squad.

How tin can you lot minimize procurement risks?

Here are a few tips to minimize procurement and supply chain risk factors and foster stiff working relationships with new vendors and existing suppliers.

#1 – Standardize procurement processes

Program your procurement processes then that anybody on your squad understands the protocols they demand to follow to ensure all data is accurate, complete, and up-to-date.

If everyone is following a standardized procurement protocol, information technology's easier to identify delays in the system and trace back accountability.

Standardized procurement procedures also mean procurement staff can nada through the procurement procedure, equally they know exactly what to do at each stage.

#2 – Deploy procurement automation technology

When it comes to spreadsheets vs software, there's but one winner — a modern procurement process must use modern tools.

If you lot're a big concern or you process large transactional volumes, a total-fledged e-procurement organization similar SAP Ariba might be the right solution. Sure, these enterprise software packages are highly-customizable, but they're often very expensive.

For everyday businesses, a straightforward, no-code procurement automation solution solves the bottlenecks caused by manual procurement processes.

Duplicate data entries and manual errors become a affair of the past, replaced with mod online electronic forms, congenital-in mobile and e-signatures, and automatic routing. This ways faster procurement processing and no more chasing approvals. Your team can focus on their main roles rather than wasting time fixing incorrect paperwork and hunting downwards signatures.

Want to automate your procurement process?

frevvo makes information technology like shooting fish in a barrel to speedily automate your procurement workflows with simple, elevate-and-drop tools

Try information technology free for 30 days.

#3 – Improve user advice

If you lot misinterpret user needs, yous'll purchase the wrong products. Meliorate communication with end-users to boost gamble mitigation.

Emphasize the importance of solid functional requirements, obtain a articulate statement of demand, and piece of work with users to create practical and realistic timelines that take into account lead time for procurement.

#four – Develop supplier relationships

As nosotros've seen, globalization carries intrinsic risks. Nonetheless, the benefits are simply too large to ignore. That requires a mindset change.

Foster real, collaborative relationships with your vendors and then yous can piece of work together to iron out kinks that may arise without butting heads.

Employ procurement technology to streamline purchasing processes, advice, and feedback mechanisms so there aren't unnecessary delays in the vendor supply concatenation.

Final thoughts

At present you have a firm grasp on the procurement risks, you'll understand why a thorough chance assessment is crucial.

Information technology's articulate that technology is leading the manner in reducing risks in procurement processes. Reducing time spent on menial tasks, eliminating errors, and automating fundamental functions, yous'll discover procurement risks significantly lower when information technology's easier to monitor the whole procurement process in one place.

Desire to find out more virtually how you can reduce procurement risk factors with freevo? Sign up for a complimentary trial at present.

mcgeemosperwrongs.blogspot.com

Source: https://www.frevvo.com/blog/procurement-risks/

0 Response to "Reviewing Performance Records Reduces the Risk of Selecting a Supplier With a Poor Track Record"

Post a Comment